Sustainability

Recycling Initiative: We collect and recycle a substantial amount of soft clean waste from our weaving factories, reintroducing these materials into yarn production through MJS and open end processess without compromising quality. This reduces the need for fresh material purchases.

Collaborative Efforts: We are committed to increasing the use of recycled materials by educating and encouraging other factories to join our recycling efforts.

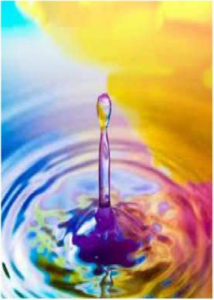

Water Conservation: Adoption of Benninger’s Triko Flex Technology has reduced water use for washing reactive prints in home fashion by 50%, from 90 liters/kg to 45 liters/kg. We aim to further reduce this to 30 liters/kg.

Sustainability Initiatives

Energy Efficiency: Installed a new turbine in our co-generation plant, increasing electric output by 2 MW and achieving a 15%+ reduction in fossil fuel/biomass use annually.

Renewable Energy: Increased use of solar power with 1 MW installed at our stitching facility and 3 MW at our production facilities. We aim to double renewable energy use every three years, significantly reducing fossil fuel usage.

Carbon Footprint Reduction: Piloting a new dyeing process, PS2, in collaboration with Rotaspray, reducing power and gas consumption by 30%-40% and cutting carbon footprint by over 18%.

Sustainable Processing & value-added solutions

- Pigment dyeing

- Soft pigment printing

- ECO Safe/formaldehyde-free printing

- Sensible reduction of water and chemical consumption

- PPE bags with 30% recycled content, fabric bags, and 100% recycled cardboard boxes